V-Band Flanges

What is a V band Flange?

A universal V band flange is a method of connecting pipes together in conjunction with a v band clamp, The Vband flange is welded to the exhaust tube and then bolted together with the vband clamp. These are used mainly in the automotive industry for exhaust systems and waste gate return pipes.

There are a range of different types of v band flanges, these are also used for turbo inlet & outlet's, external waste-gates & intercooler piping.

"QUICK TIP"

"ADD ANTI-SEIZE TO THE THREAD OF THE CLAMP TO PREVENT THE NUT AND THREAD FROM BINDING WHEN LOOSENING AND TIGHTENING" IF YOU UNDO THE CLAMP WHILE THE V-BAND IS HOT YOU WILL INCREASE THE CHANCES OF THE THREAD BINDING DUE TO THERMAL EXPANSION.

Different types of V band flanges

-Universal Exhaust V bands

-Turbo Inlet & Outlet V bands

-Wastegate V bands

How do V band flanges work?

V band flanges work along with a v band clamp, most exhaust v band flanges do not require gaskets and they can get away with no gaskets due to there design and how they are manufactured. They have a tapered design machined onto them where the clamp sits, the tighter the clamp gets the more tension is applied to the x2 v band faces pulling them together. Also when the flanges heat up they expand and this causes them to seal even more.

If your v band flange is distorted then you will struggle to seal the x2 faces together so it is important to minimize the distortion when welding.

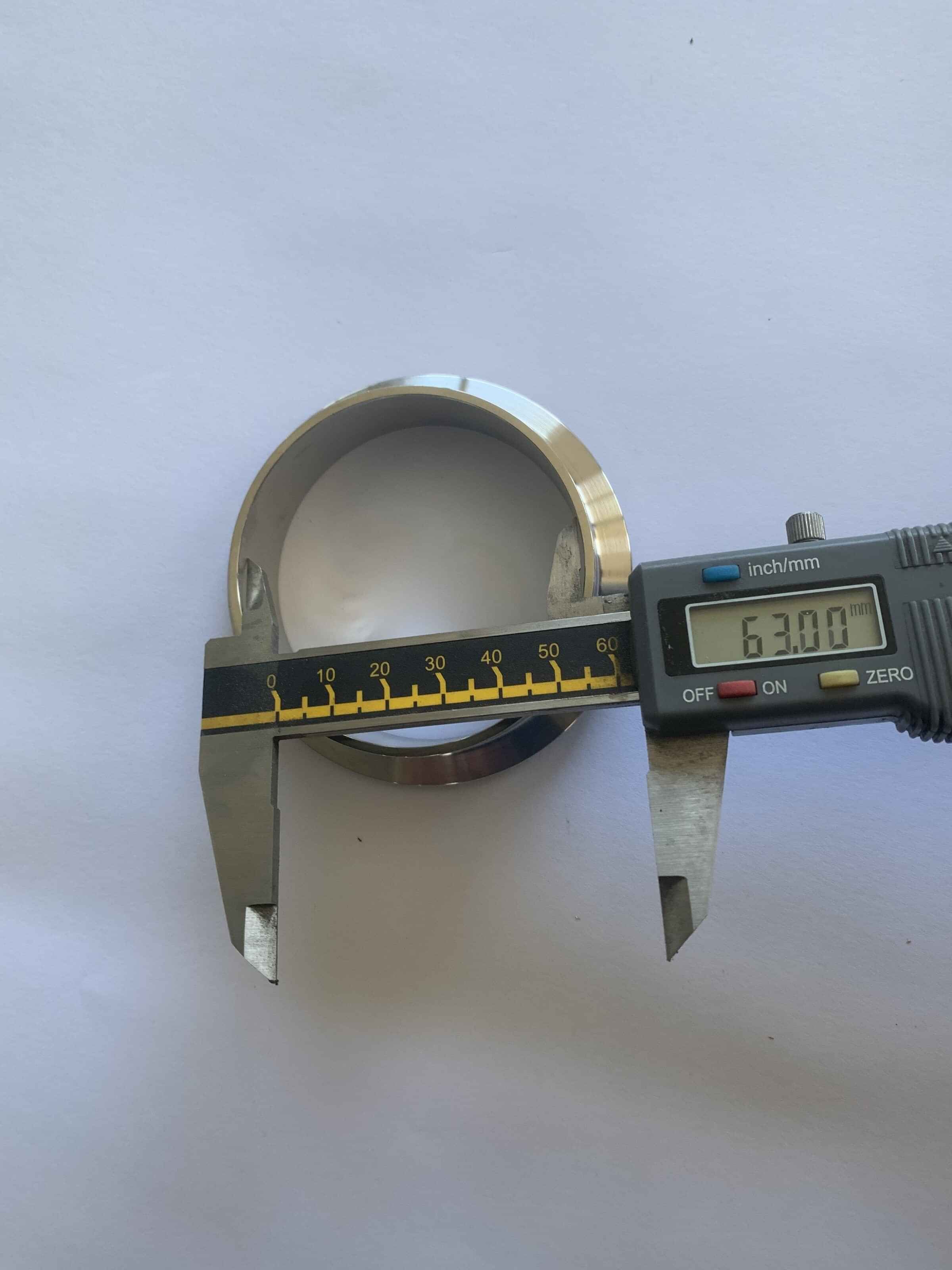

How to measure V band flanges

All v bands are slightly different from universal v band sets, turbo outlet and inlet v bands & waste gate v bands. All manufactures make them to suit there own requirements, so none of them are a "one size fits all". You will need to check the dimensions before purchasing a v band for a certain turbo or waste gate. For example a 45mm universal v band flange or clamp will not necessarily suit a 45mm waste gate. The waste gate will have its own v band flange & clamp specifically designed for that model.

Flat V bands

These are relatively simple to measure, there is a outside diameter and an inside diameter (the inside diameter would be known as the tube diameter measurement) and this is displayed in the picture below.

Male/Female V bands

Male & female v bands are a bit more complicated, there is the outside and inside diameter and then there is the recessed section which needs to be measured from the outside diameter of the recess itself and then the depth of the recessed section. If the depth of the recess is to big then it will bottom out in the female section of the vband flange and not bolt up together correctly, this will cause it not to seal.

V band Clamps

One issue you can face when trying to match a v-band flange & clamp to a rear housing of a turbo or any other application is the retainer section of the v-band clamp can bottom out on the body of the turbo or flange.

This can be overcome by cutting a small section of the retainer lip off so it will not bottom out on the body section and be able to be tightened up correctly.

How to weld V band flanges

The main issue you will face with welding v band flanges is distortion. A universal v band set requires a lot less heat than welding turbo inlet V band flanges so this needs to be considered. There are a few ways that you can help minimize distortion and we have listed these below.

x6 helpful tips to prevent Vband flanges from distorting when welding

- The more tacks the better - we recommend a tack every 10-15mm

- Try welding 20-30mm at a time and letting this section cool this allows the v band not to get to hot

- When welding a universal v band set you can clamp the two v band flanges together to minimize the distortion

- When welding a turbo inlet or outlet v band you can clamp the flange to the turbo inlet or outlet of the turbo housing itself

- When welding a waste gate v band flange then try clamping the flange to the waste gate

- If you don't have another v band to clamp to you can get a flat plate and drill a series of holes in the plate and clamp it down using large washers with bolts (the other methods above are much more successful to help distortion but this method along with welding small amounts at a time does work) We recommend at least x4 bolts to clamp it down.

V band Flange vs Exhaust Flange

When fabricating an exhaust both of these options serve the same purpose to connect sections of the exhaust or pipes together.

The v band flange has a few different aspects from the exhaust flange and we have listed these below:

V band Flange

- V band flanges do not require gaskets so this can be an advantage

- V band flanges have no way of locating orientation so can be tricky to align once taken apart, if there are all v bands connecting your turbo, waste gate & exhaust system together it can take some time to get them all back in exactly the same position.

- The V band flange is more compact than the exhaust flange so can give better ground clearance when using to fabricate an exhaust system

Exhaust Flange

- Exhaust flanges require gaskets so this can be a dis-advantage due to these blowing out if the flange is distorted or the flange loosens

- Exhaust flanges locate the orientation with bolts so can be re-aligned easily when re-fitting an exhaust system or waste gate pipe